Our products are put through rigid tests which show how much superior they are compared to ISU standards:

Drop Test

Furthermore, even the external cover of all ImpaKt products, is of a higher level compared to the most used common mats:

Cover Sheet Specifications

Special cut resistant textures are under evaluation and testings for a future application, with the main goals to keep the softness of the cover sheet and to guarantee the resistance which distinguishes ImpaKt products.

Speed Skating and Short Track Safety Systems

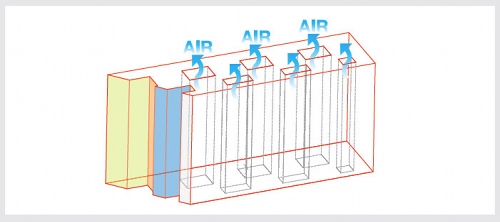

The excellent results of the protections are reached with a special inside structure made of different layers of foam. The front part is made of a special shock-absorber with slow memory, able to absorb the first phase and speed of the impact, avoiding a severe impact for the athlete. The other components of the protections are realized with different layers of foam with different density and an open cell structure. This open cell structure is studied to guarantee the right proportion between air volume and foam mass, mandatory for the correct cushioning and reduction of speed of the colliding athlete. The foams are specially chosen based on their compression factors and deformation, which at the moment of the impact have to compress to a limited extent, evacuating the air across the appropriate open air channels. Each single system has different inside structures which were especially studied and tested to reach the highest possible impact force and bounce back reduction.

The internal part of the mat is made up of several kinds of foam, which have different thicknesses and shapes. Viscoelastic foam and rebounded foam have a real efficacity. The viscoelastic low resilience foam has been engineered and performed for the aerospace industry for the positioning of astronauts. With the aim of obtaining the maximum distribution of the compression load in static and dynamic conditions. The viscoelastic low resilience material is self-shaping: this property allows distributing the body weight uniformly on the whole surface, avoiding some parts being overweighted. The viscoelastic foam comes back to the original shape even after heavy and long term pression and assures a good shock absorbation. The foam, with its completely open cells, assures an excellent speed of air escaping. An agglomeration is by definition a compacted material, obtained from hot-pressed particles (granules) mixed with substances that will in turn glue the elements. An agglomeration offers an optimum resistance to compression over time, which is different from a normal foam. It has a compressed cellular structure instead of a free structure. Therefore, not like a normal foam, the cells, being already compressed, suffer a minimally negligible deformation with time.

A greater compression of the mix corresponds to an increased agglomeration density and therefore the greater density corresponds to a better resistance to compression.